How To Install A Bow Window

How to Install a Bow Window

Updated: Jun. 25, 2019

How to frame a rough window opening, install a new window, trim out the interior and exterior around a new window, plus all of the finishing.

We'll walk through the steps needed for bay window structure, which volition give your room a lot of natural low-cal and a spacious feel. The new window will also update the expect of your house. Framing and installing the new window may seem similar a daunting job, but if you lot're an ambitious exercise-information technology-yourselfer, you can handle the job successfully by following our detailed instructions and how-to photos.

You might also like: TBD

- Time

- Complexity

- Toll

- Multiple Days

- Advanced

- $501-1000

A project that's as easy or hard as y'all want it to be

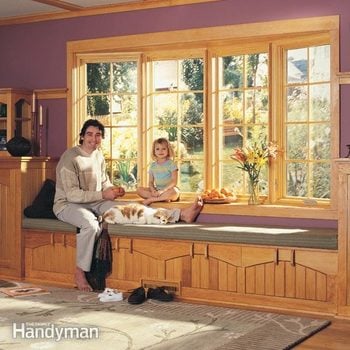

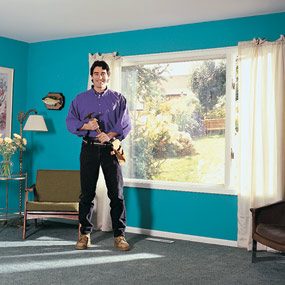

Replacing an aging picture window with a new bow window produces lots of benefits. It provides improve ventilation, better views and better comfort. Information technology updates the wait of your house, both inside and out. And it provides a great identify for your cat and plants to sunbathe.

Merely what I similar well-nigh is the style a bow window makes a room look and feel larger—even though the "bulge" adds just a few foursquare anxiety. They're a great addition to a living room, dining room or family unit room, and have a particular knack for making a cramped eating nook experience roomier.

The steps for installing a bay window—one that juts out farther, usually at a thirty- or 45-degree angle—are nearly identical to those for a bow window. In fact, the first role of this article provides the basic steps for installing whatever window.

How tough is this bay window construction projection? Well, to some extent, you become to choose. If the thought of bracing up and fierce into your firm to install a new header (Photos iii and 4) is daunting, purchase a window that's the same size every bit or slightly smaller than the existing one. Yous won't need to tackle the major structural work, making this a project a confident beginner can do. Creating a new opening for a taller window isn't that much more than hard; yous simply lower the sill by shortening the cripples (Photograph v).

Just if you lot widen the opening (and add cabinets and a window seat every bit we did), the project becomes more challenging. You'll be tackling both brawny rough carpentry piece of work and detailed finishing work, perchance even rerouting oestrus ducts and electrical wiring. You'll demand to exist comfortable handling ability tools and allot plenty of time to finish the projection. Our bow window was 6 in. wider and 4 in. shorter than the moving picture window it replaced, and so we took the hard road.

Either way, formulate a game plan so you can pull out your erstwhile window and go the new window installed in the opening in a single mean solar day. This means having the room cleared out, temporary back up wall (if necessary) in place, tools and materials at the ready, new window on site and helpers lined up ahead of time. You don't want to lie awake in bed at dark wondering if hail, bats or the boogeyman will be crashing through flimsy plastic stapled beyond an unfinished opening.

Remove the old window

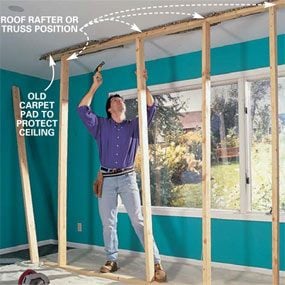

You'east going to make a dusty mess, so move the furniture out, seal up the ducts, lay downwardly a dropcloth and encompass the doorways with plastic. If you're installing a larger header for a wider opening, you'll need a building permit. Some inspectors will help you decide the correct header size; others will require calculations from a structural engineer—especially for openings exceeding 8 ft.

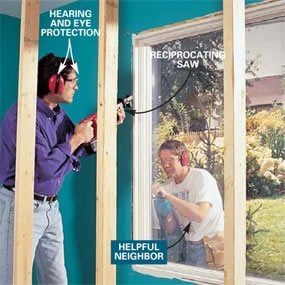

If yous're installing a larger header, build a temporary support wall (Photo 1) 2 ft. back from the existing wall. Advisedly pry the interior molding from around the window with a flat bar, so fix information technology aside. You lot may need to reuse information technology, since some older moldings are hard to friction match. Employ a reciprocating saw to cut through whatsoever finish nails that secure the window jamb to the window opening (Photo two).

Use a pry bar to remove the trim or brick mold that surrounds the window outside and helps hold it in place. Be careful; sometimes your window will come up out forth with it. If your window is metal or vinyl clad, congenital-in nailing flanges may exist securing information technology to the exterior capsule and framing. If removing the exterior trim doesn't give you access to these nails, use a round saw (Photo 2) to cut back the siding 2 in., then remove the nails with a apartment bar. With the help of your spouse, neighbors and kids, remove the window.

Brick, stucco and other types of siding nowadays their own unique challenges. Cut back or remove merely every bit much of these materials every bit necessary to become the old window out and the new window in. Yous can try to patch gaps betwixt the edges of the window and the remaining siding, brick and stucco with similar materials, but getting an verbal match tin be hard. Filling gaps with broad trim boards is often lots easier.

If you're installing a larger header, close off power to all electrical outlets and switches in the wall, then remove the drywall or plaster. Nosotros removed everything "down to the studs" along the unabridged wall; it's easier to fit and tape all new drywall or plaster, corner to corner, than to match the thickness and textures of the quondam and the new. It also allowed united states of america to upgrade the insulation and install cable and a new phone line.

Tip:

Your temporary support wall can practice double-duty; staple plastic to it to help contain the droppings and grit.

Framing a new rough opening

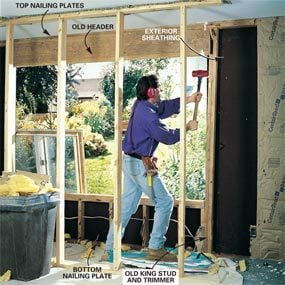

Employ a sledgehammer to knock the king studs and trimmers away from the ends of the existing header (Photo 3). If sheathing and siding nails are fastened, cut through them with a reciprocating saw or yank them out with a "true cat's manus" smash puller. Remove the sill, too. Decide the window rough opening width. Manufacturers list the rough opening height and width with each window. Ours was 100-three/viii in., so nosotros cut our headers 106-3/eight in. long—half dozen in. longer to accommodate the two pairs of 2×4 trimmers (Photo 6).

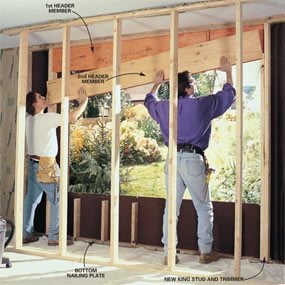

Toenail the new king studs and one trimmer to the top and bottom nailing plates using 16d nails and install the two header members (Photograph four). Toenail the top of the header into the summit nailing plates, and so add the second trimmers.

Determine the rough opening height, then "sister" new cripples alongside the existing ones to raise the sill elevation (Photo 5) or cut them shorter with a reciprocating saw to lower it. Smash the sill to each cripple and to the trimmers on each side. We installed two sills to solidify the large opening and support the window.

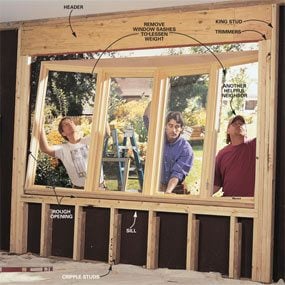

Rally your neighbors to hoist in the new window

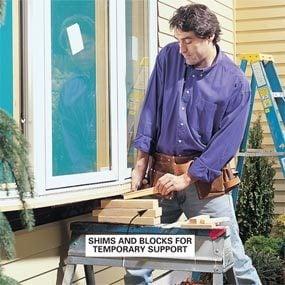

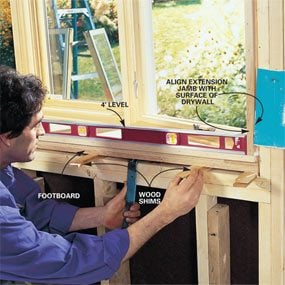

Rustle upward your neighbors over again and elevator the new window into the rough opening (Photo half dozen). Temporarily support the window (Photo 7), so on the inside, utilise a apartment bar to centre the window in the opening from side to side. Shim and level the footboard (Photo 8). Next, use the level and shims to plumb and straighten the side jambs.

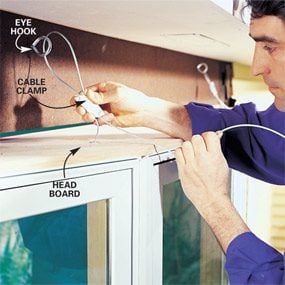

Shim the superlative directly and level likewise. When all four sides are level, plumb, square and straight, drive 10d finish nails through the extension jambs and shims into the framing. Take your time. Since bow windows extend beyond the exterior wall, they demand added support (Photos 9 and 10). Our Pella window came with two preinstalled cables running from the bottom of the footboard upwardly through the headboard. If space is limited above the window, secure the cables to the rafter tails or to blocking that's deeply nailed betwixt the rafter tails.

Tip for bay window construction:

Remove the operable window sashes to lighten the weight, especially if you're working off ladders.

Trim the exterior carefully—so the window doesn't look "stuck on"

Bay window structure:

The closer you lot lucifer the exterior details to those of the existing business firm, the more natural the window volition await. Since every house is a piddling different, your exterior trim details volition almost certainly vary from ours, peculiarly if you lot accept brick, stucco or vinyl siding. But the aforementioned general steps still utilize.

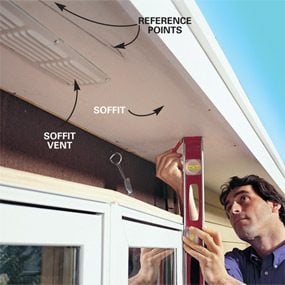

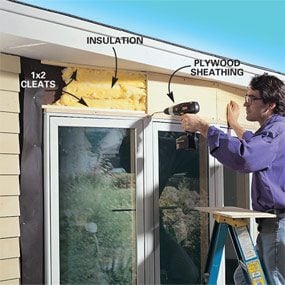

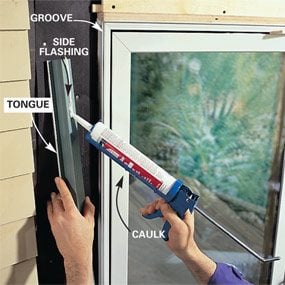

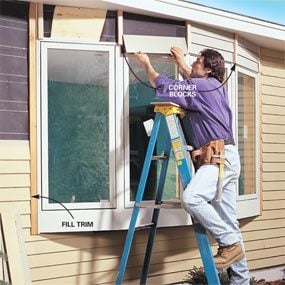

Begin past insulating and enclosing the bottom (Photo11). Concur your iii/8-in. plywood soffit textile to the underside of the window, trace the profile onto it, then use a circular saw to cut it to shape. Use this as a pattern to cut the 2-in. rigid insulation and the 3/four-in. plywood nailer. Make sure the edges of all three layers are even with the edges of the bow window as y'all install them. After enclosing the top (Photos 12 and 13), install the side and lesser flashings (Photos 14 and 15). If the top of your window is within six in. of the soffit, you lot tin insulate it, then enclose it using the same flashing fabric and technique shown in Photo 15. Larger spaces crave yous to install sheathing (Photo xiii), and so siding (Photo sixteen).

Install matching siding materials or trim boards to fill the gap at the sides of the window if necessary. Rather than boom in a row of little 6-in. siding pieces along the left side of the window (tacky, tacky), we removed the siding dorsum to the corner and installed full-length siding pieces that butt to the trim board (Photo 16).

Tip:

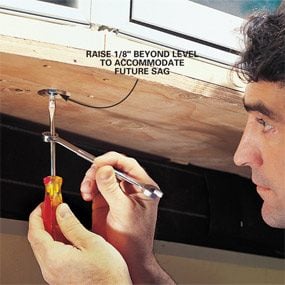

Level the footboard, and then heighten information technology an extra 1/8 in. using the cable nuts. That way, when the cables stretch and the rafters or header they're fastened to 'gives' a niggling (and that's inevitable), the window will current of air upward level.

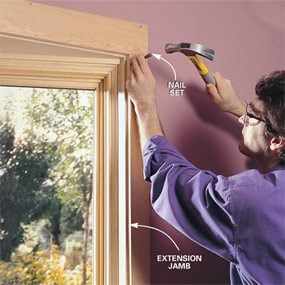

The interior details

Use a wood shim to loosely stuff fiberglass insulation into the thin space betwixt the extension jamb and rough opening. Hang, tape and sand the drywall, then paint it. Recut and reinstall the old interior moldings. If they're not long plenty or you're completely redoing the room equally nosotros did, install new moldings (Photograph 17).

Nosotros added a window seat with a hinged top for storage, besides as built-in cabinets to consummate the projection. This meant adding a xc-degree elbow to the existing floor heat duct and extending it through the face up of the window seat. We left the old electrical outlets in the backs of cabinets to power the audio equipment inside.

You lot're done. Take a bow.

Window Shopping and Planning

We installed an eight-ft. 5-in. x 4-ft. 8-in. Pella Designer Serial iv-console bow window. The approximate $iii,000 cost tag included grilles, extension jambs and flashings. Most major window manufacturers offering bow windows, available with iii to seven panels, ranging in width from 6 to 14 ft., and in a multifariousness of heights. Prices start at nigh $800. Before placing your social club, determine whether y'all tin can tuck the window under your eaves, similar we did.

Our eighteen-in. eaves hands accommodated and sheltered the 12-in. projection of our window. Only if your firm has narrow eaves or yous're installing the window on an unprotected section of wall, you'll need a roof. Some manufacturers can put you in touch with a prefab roof supplier or provide design guidelines for experienced practise-it-yourselfers to build their own. It's a challenging job we don't cover hither.

Measure the combined thickness of your wall studs, outside sheathing and drywall or other interior wall surface to make up one's mind the proper depth of your window'south extension jamb (Photograph 8). A mutual thickness is four-9/16 in.: i/2-in. capsule + 3-1/two in. stud depth + 1/two-in. drywall + 1/16 in. of "play" = 4-nine/16 in. Include this information when you society your window so the edge of the jamb will exist fifty-fifty with the drywall, and your interior moldings will fit flat when installed.

Required Tools for this Projection

Have the necessary tools for this DIY project lined up before you start—you lot'll save time and frustration.

Required Materials for this Project

Avoid last-minute shopping trips past having all your materials ready ahead of time. Here'south a list.

Originally Published: June 25, 2019

Source: https://www.familyhandyman.com/project/how-to-install-a-bow-window/

Posted by: maplethoposel.blogspot.com

0 Response to "How To Install A Bow Window"

Post a Comment